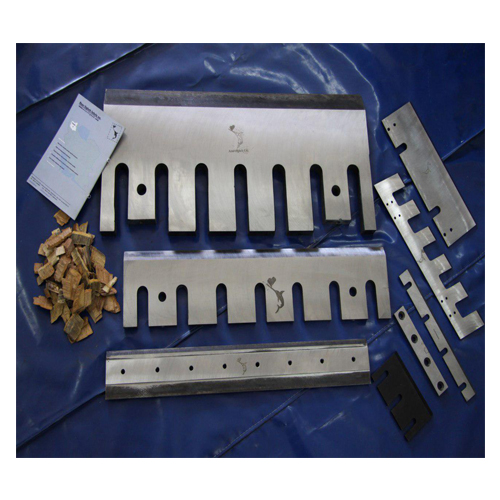

The blades produced by this company for the particleboard and MDF industries are made from high-quality chrome-alloy steel and undergo a proprietary hardening process. In this process, only the working edge and the full thickness of the blade are hardened, achieving maximum hardness, wear resistance, and flexibility.

The high flexibility of these blades eliminates the risk of breakage during service or accidental contact with foreign objects, which is a significant advantage in heavy-duty chipper machines.

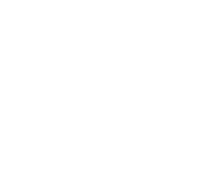

Product Types:

Light and Heavy Wood Chipper Blades (including Chipper, Flicker, Grinder, Meyer, etc.)

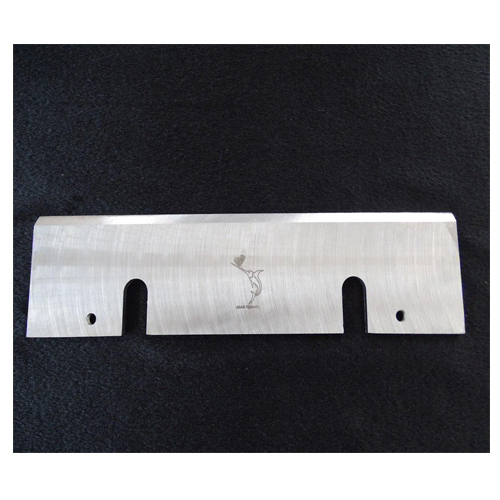

Anti-Blade Blocks

Wood Veneer Cutting Blades (Peeler and Slicer)

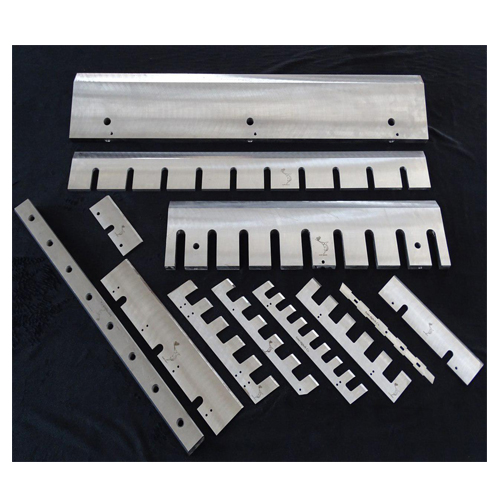

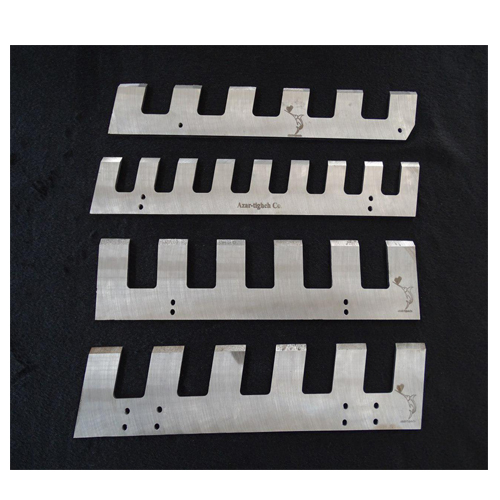

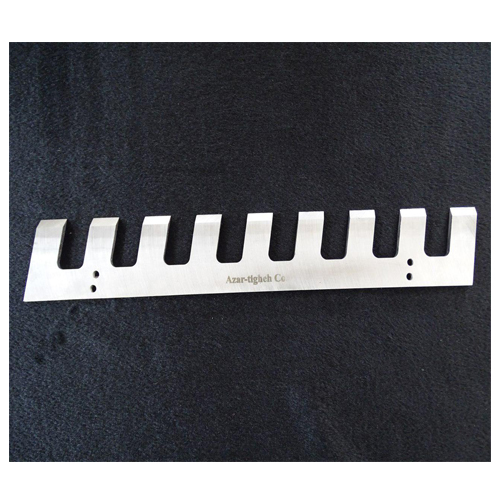

Chipper Blades:

Used in heavy wood and forest waste chippers for particleboard and MDF production, these blades are frequently exposed to hard objects, which has historically caused serious accidents. In this unit, they are selectively hardened using a proprietary method: only 6 mm of the blade thickness and 70 mm of its width are hardened up to 55 HRC, ensuring that the blade will not break under any circumstances and is completely safe.

This design eliminates the risks associated with heavy machinery due to blade breakage or damage to personnel and equipment. It has no foreign equivalent and is produced exclusively in this unit.